Generally I am pro bio-gas, given that the optimized diversion of manure to bio-gas production by means of anaerobic digestion results in a negative value for production and is the only alternative fuel to do so in the Zah study. On the other hand, I have been cautious about endorsing the use of LFG (Land Fill Gas). Likewise, I have been critical of powering vehicles with CNG (Compressed Natural Gas).

Bio-gas, a.k.a., renewable natural gas, is a versatile energy source. Anaerobic digestion is a way to process manure that can reduce odor and water quality issues.

Nevertheless, with the double jeopardy of climate change and peak oil, it would seem that WM has a winner if it can ensure clean, efficient means of producing such fuels and ensuring that there combustion produces very low amounts of GHG emissions. How much of a winner then will depend upon future federal incentives and the cost of petroleum. If oil prices remain unexpectedly low and federal incentives withheld, then WM might forestall development since bio-gas is in the middle of the pack in terms of cost, efficiency, import dependency, fuel price sensitivity and proved reserves. While such scenarios are possible, it is much more likely than oil prices will rebound and there will be federal incentives consistent with IPCC recommendations for which Waste Management qualifies.

WM operates 281 landfills in North America; 100 already have some form of methane-to-energy capabilities; and, last June plans were announced for landfill gas-to-energy facilities at 60 additional sites. If the sooner that oil prices rebound, the greater the economic incentive for WM to invest in multi-step upgrading of land fill gas.

According to the Environmental Protection Agency, landfills are the largest source of methane emissions in the United States, accounting for 34 per cent of such releases. Methane is one of several non-CO2 gases that contribute to global climate change and chemically 20 times more hazardous that carbon dioxide

The trucks use Autocar chassis and McNeilus (an Oshkosh Corporation) bodies. McNeilus expects to deliver the remaining CNG vehicles to Seattle in late March 2009. McNeilus is also providing 40 CNG refuse trucks to Cleanscapes, the other contractor for refuse collection in Seattle under recently awarded contracts.

Waste Management is putting the new trucks into service as they arrive and has a dozen already on the job in Seattle. The full complement of 106 CNG trucks will be in service when Waste Management begins its new collection contract with the city of Seattle on 30 March. Construction on the fueling depot is scheduled to be complete in April. The station will service the new fleet and also be open to the public.

Waste Management is investing $29 million in the new vehicles and an additional $7.5 million to build the fueling station. The new trucks are six times cleaner than diesel engines manufactured in 2007 and meet the US Environmental Protection Agency (EPA) 2010 emission standards for oxides of nitrogen (NOx) and PM.

An independent environmental review produced by Gladstein, Neandross & Associates, a environmental consulting firm, determined Waste Management’s equipment upgrade will reduce smog-causing NOx by 97 percent, toxic diesel particulate matter by 94% and greenhouse gas by 20%, over current levels. Switching to advanced CNG vehicle operations will provide significant environmental, public health and community benefits to the region. The collection trucks also will reduce noise pollution.

Within five years all 180-collection trucks in Waste Management’s Seattle-based fleet will be fueled by CNG.

Background. Waste Management (WM) has been providing services under contract with Seattle Public Utilities (SPU) for twenty years. The other waste collection provider under the current set of contracts, which end in March 2009, is Allied Waste, Inc. Following a number of problems with Allied Waste, SPU issued a Request for Proposals (RFP) for solid waste collection and transfer services across four geographic sectors, rather than the current two, in February 2007. Waste Management, Allied Waste and Seattle-based newcomer CleanScapes submitted proposals; SPU chose WM and Cleanscapes.

The 10-year contracts required CleanScapes and Waste Management to purchase all new collection trucks before beginning service in April 2009. All collection trucks are required to meet 2007 Federal Diesel Engine Requirements or to operate on CNG or LNG. Waste Management runs its current collection fleet on diesel. Both WM and Cleanscapes are using CNG under the new contract.

Image credit: Environment Ministry Of Canada, Quebec

At its South Seattle operations headquarters Waste Management of Seattle broke wind ground on its new compressed natural gas (CNG) fueling station.

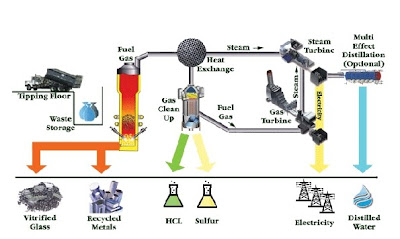

By developing WM also prepares for future eventualities. Upgraded bio-gas can be used to generate electric power that could be used on site, for grid-able hybrid vehicles (to include bio-gas range extended electric vehicles, and sold. Even though there are greater efficiencies to using electric drive, plus heat recovery sent back to gas conditioning and anaerobic digestion processes, much depends upon the cost of batteries. Although a less ubiquitous infrastructure than the Grid, connection to the natural gas infrastructure is another strategic advantage to bio-gas development.

…rise in the use of landfill gas can be attributed to a variety of factors. Higher energy prices make landfill gas cost-competitive, especially compared to other sources of renewable energy. Second, utilities are looking for new sources of renewable energy to meet renewable portfolio standards, and landfill gas is especially valuable to them because it provides base load power. There’s also a real demand from consumers for greener energy and many of them are taking part in voluntary programs and are willing to pay more for power derived from renewable sources.

Wes Muir, Director of Communications for Waste Management, Inc,

Other AG Posts Possibly Related :

• First of Its Kind

• Bio-gas Pros… and Cons

• A Tip for Town Managers / Supervisors

• Another Plug-in Hybrid Retrofit Kit