>Agriculture Biogas Recovery

>Plasma Gasification

>Landfill gas

>Current and Future Applications

Agriculture Biogas Recovery

Biogas recovery systems at livestock operations can be a cost-effective source of clean, renewable energy that reduces greenhouse gas emissions. Because of its high energy content, biogas can be collected and burned to supply on-farm energy needs for electricity or heating. In 2005, about 100 systems were operational or under construction in the United States, and another 80 in the planning stages. However, biogas recovery systems are estimated to be technically feasible at about 7,000 dairy and swine operations in the U.S. These facilities offer a substantial business opportunity to increase farm income.

What is Plasma Gasification?

Plasma gasification is a new garbage disposal solution using plasma technology. This process of garbage disposal is self-sustaining and converts garbage into electricity. Although plasma technology has been around for years, its application to garbage disposal was never seriously considered because the conventional approach of using landfills was less expensive (even with tipping fees and transportation costs). It was only recently - with landfills in scarce supply and with fuel costs on a constant rise - that the plasma gasification process has merited deeper consideration.

Plasma Technology

The basics of plasma technology are straightforward. A high-voltage (650-volt) current is passed between two electrodes to create a high-intensity arc, which in turn rips electrons from the air and converts the gas into plasma or a field of intense and radiant energy.

This is the process behind fluorescent and neon lighting where low voltage electricity passing between electrodes in a sealed glass tube containing an inert gas excites the electrons in the gas. The gas releases radiant energy and electric arc welding or cutting; this electricity passing between electrodes creates plasma that can melt metal.

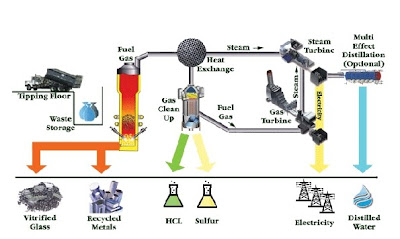

Plasma Gasification

First, garbage is fed into an auger, a machine which shreds it into smaller pieces. These are then fed into a plasma chamber - a sealed, stainless steel vessel filled with either nitrogen or ordinary air. A 650-volt electrical current is passed between two electrodes; this rips electrons from the air and creates plasma.

A constant flow of electricity through the plasma maintains a field of extremely intense energy powerful enough to disintegrate the shredded garbage into its component elements. The byproducts are a glass-like substance used as raw materials for high-strength asphalt or household tiles and "syngas".

Syngas is a mixture of hydrogen and carbon monoxide and it can be converted into fuels such as hydrogen, natural gas or ethanol. Syngas (which leaves the converter at a temperature of around 2,200 degrees Fahrenheit) is fed into a cooling system which generates steam. This steam is used to drive turbines which produce electricity - part of which is used to power the converter, while the rest can be used for the plant's heating or electrical needs, or sold back to the utility grid.

Therefore, aside from the initial power supply from the community's electrical grid, the whole machine can produce the electricity it needs for operations. It also produces materials that can be sold for commercial use so, at some point, the plasma gasification system will generate profit for its users.

Landfill gas (LFG)

Municipal solid waste landfills are the second largest source of human-related methane emissions in the United States, accounting for approximately 23 percent of these emissions in 2007. At the same time, methane emissions from landfills represent a lost opportunity to capture and use a significant energy resource. Landfill gas (LFG) is created as solid waste decomposes in a landfill. This gas consists of about 50 percent methane (CH4), the primary component of natural gas, about 50 percent carbon dioxide (CO2), and a small amount of non-methane organic compounds.

Instead of allowing LFG to escape into the air, it can be captured, converted, and used as an energy source. Using LFG helps to reduce odors and other hazards associated with LFG emissions, and it helps prevent methane from migrating into the atmosphere and contributing to local smog and global climate change.

Landfill gas is extracted from landfills using a series of wells and a blower/flare (or vacuum) system. This system directs the collected gas to a central point where it can be processed and treated depending upon the ultimate use for the gas. From this point, the gas can be simply flared or used to generate electricity, replace fossil fuels in industrial and manufacturing operations, fuel greenhouse operations, or be upgraded to pipeline quality gas.

The generation of electricity from LFG makes up about two-thirds of the currently operational projects in the U.S. Electricity for on-site use or sale to the grid can be generated using a variety of different technologies, including internal combustion engines, turbines, microturbines, Stirling engines (external combustion engine), Organic Rankine Cycle engines, and fuel cells. The vast majority of projects use internal combustion (reciprocating) engines or turbines, with microturbine technology being used at smaller landfills and in niche applications.

Directly using LFG to offset the use of another fuel (natural gas, coal, fuel oil) is occurring in about one-third of the currently operational projects. This direct use of LFG can be in a boiler, dryer, kiln, greenhouse, or other thermal applications. It can also be used directly to evaporate leachate. Innovative direct uses include firing pottery and glass blowing kilns; powering and heating greenhouses and an ice rink; and heating water for an aquaculture (fish farming) operation. Current industries using LFG include auto manufacturing, chemical production, food processing, pharmaceutical, cement and brick manufacturing, wastewater treatment, consumer electronics and products, paper and steel production, and prisons and hospitals, just to name a few.

Current and Future Applications

The benefits of the system are evident. It is self-sustaining after the initial electrical charge is used; it is environmentally friendly; and it produces materials that have commercial applications or use and thus can generate profit.

Aside from disposing of newly-produced garbage, the system can also be used to dispose of accumulated landfill garbage so land reclamation is entirely possible. Another application planned is using the syngas as a base for producing hydrogen in commercial quantities, which will be used as fuel for hydrogen-powered vehicles.

See More ..

Tidak ada komentar:

Posting Komentar